PLUG & PLAY SOLUTIONS

Proposed P2ENDURE multifunctional panel.

The EASEE prefab panels are composed of two layers of Textile Reinforced Concrete (1.2 cm each) and insulation core between them made of expanded polystyrene (10 cm). The total thickness of the panels is 12.4cm. The thickness of the insulation may be increased if needed. The width of the panel is in the range of 0.5m-1.5m and the height 1.5m – 3.0m. The weight of the panel is around 54 kg/m2. The anchorage system allows achieving flexibility and capability to adapt to different architectonic configurations and building typologies. The panels can be attached to the concrete slabs or to the brick/cellular concrete blocks. When applied, these panels increase the thermal properties of the envelope after retrofitting (U<0.23 W/m2K for retrofitted wall), reduced installation time by 50% in comparison with traditional retrofitting, high aesthetic properties that allows application of the solution to buildings under cultural heritage protection. P2ENDURE adopts, enhances and implements the innovative prefab EASEE panels, which have successfully been tested in field demonstration in Gdańsk (PL) and Milan (IT).

Proposed P2ENDURE smart energy-efficient window.

Windows that can be rotated by 180° to reduce the thermal radiation from the outside during summer season, and reduce the thermal dispersion from the interior in the winter, thanks to the double positioning of the low-E glass. The smart window provides natural ventilation, rotating and locking mechanisms which enhance anti-burglary features, as well as integration with state-of-the-art domotics solutions. It satisfies the needs for high energy-efficiency, better indoor climate, and top class security features.

The reversible window technology is enabled by innovative hydraulic gaskets and burglar-proof electro-magnetic locking mechanisms fully integrated in the frame. There are 3 affordable innovative components: 1) Active gaskets allowing sealing, ventilation or release with simple hydraulic or pneumatic systems; 2) Structure of the frame with rotating sash across either horizontal or vertical axes; 3) Window locks and control system, with possible integration with building automation, HVAC (Heating, Ventilation and Air Conditioning) control systems and centralized security features.

%20lr.jpg)

%20lr.jpg)

%20lr.jpg)

Check out the Factsheet

Check out the Factsheet

Proposed P2ENDURE folding balcony.

Bloomframe® is an innovative window that transfers into a balcony at the touch of a button. The engineering was finished in 2015; the final prototype was presented at the international construction exhibition BATIMAT 2015 in Paris; the first sales and applications will start in 2016. The Bloomframe® folding balcony is designed by Hofman Dujardin Architects and manufactured by the French manufacturer Kawneer, a global leader for aluminium facades, windows and doors based on the Alcoa window system.

The Bloomframe® folding balcony is applicable for both new building and deep renovation projects. The advantages of the concept are especially clear in transformation projects were housing is realized and a regular balcony is not possible or not allowed while residents in congested urban areas demand private outside space to enjoy the weather. The cost of the Bloomframe® folding balcony as demonstrated will trend to the cost of a large window frame of the same quality and performance and a traditional balcony of the same size. The energy performance of a Bloomframe® folding balcony (high insulation rate and high solar factor) for deep renovation will help to realize zero energy target for the building, which puts the RoI (Return on Investment) realized at zero. The use of Bloomframe for deep renovation will help to realize a nZEB (nearly Zero Energy Building) with EPC = 0.15.

Proposed P2ENDURE rooftop retrofitting / extension module.

With Flat Energy, a flat roof is renovated to new-build quality with the

possibility of individual improvements, such as extra skylight or your own

energy generation. The existing construction of the flat roof will be

maintained. The existing roof is assessed for quality and risks are

inventoried. Based on this, an assessment is made of which parts must be

replaced. High-quality roof insulation is applied to the roof, which is

provided with new roof covering. The eaves are raised and the rainwater

drains are reconnected. Roof penetrations are renewed on the upper roof

and connected airtight.

Check out the Factsheet

Check out the Factsheet

Proposed P2ENDURE PnP smart connectors.

P2ENDURE will apply smart connectors for mechanical, hydraulic, electrical, air and ICT joints. These smart connectors are available under development in related projects such as EASEE and MORE-CONNECT. In EASEE the joint between the panels has been made using a low elastic modulus neutral-curing silicone sealant with outstanding ageing resistance. The silicon has been placed on polyurethane backfill material in order to reduce the danger of cracking. The elasticity remains constant at temperatures ranging from -50°C to +100°C. The high resistance to UV rays and atmospheric agents foresees that after 20 years of service under normal conditions, the joints shows no trace of superficial cracks. In the test two different colours have been chosen, grey between the light grey panels and black between the charcoal colours. Around the whole perimeter of the test façade, the cavity between the panels and the existing wall, has been close using a polyurethane foam sealant. With this the air permeability is drastically reduced and a close air cavity is created.

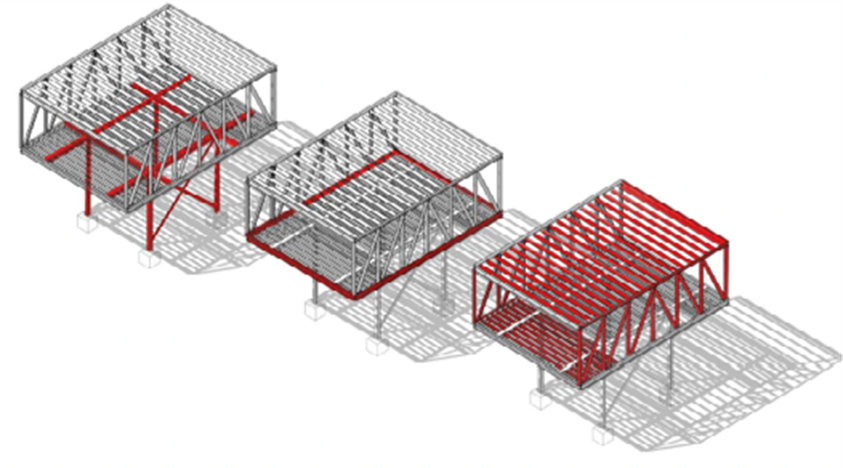

Proposed P2ENDURE PnP prefab HVAC systems.

P2ENDURE will implement a complete PnP MEP/HVAC (Mechanical, Electrical, and Plumbing/ Heating, Ventilation and Air Conditioning) engine for deep renovation. This solution includes: air-heat pump, storage capacity for domestic hot water (DHW), mechanical ventilation system, expansion barrel, and control systems. It has an extra option of split- engine (two cores), i.e. one for energy conversion and storage the other for ventilation and heating/cooling. The mounting time on-site is significantly reduced by the application of smart connectors.

This innovative solution has significant advantages: 1) the total cost of retrofitting is reduced by 40% due to efficient manufacturing and efficient use of labour; 2) quick assembly time of just 0.5 day to place engine, connect pipes/ducts, and then operate with predictable performance; 3) weight of the modules reduced by 35% compared to traditional components, due to redesign and combination of functions. This solution has recently been used for pilot implementation of deep renovation in several single-family dwellings and apartment complexes in 2 European climate zones: moderate and Mediterranean.

Proposed P2ENDURE compact energy storage.

Thermal technologies do not have such general interconnectivity and therefore rely on sizing typically meeting 90% of summer demands in moderate climates. This existing approach provides little benefit in winter. Therefore an obvious approach is that of thermal energy storage that overcomes issues of heat loss, substantially increasing the overall use of RES (Renewable Energy Sources) in buildings throughout the seasons. The innovative P2ENDURE product derived from the MERITS project is a compact seasonal storage system based on novel high-density materials that can supply required heating, cooling and domestic heat water (DHW) with up to 100% RES. Delivery of heat on different dedicated temperature levels is one of the key prerequisites of the system. Tailoring to the size of individual dwellings is a second one. The storage system must have a manageable volume comparable with the footprint of a domestic dwelling. Such a tank typically becomes between 4m3 and 8m3 and has a possibility of being incorporated under for example a garden space. The starting conditions for the dimension of storage materials and capacity, and the storage system and control system have been investigated. Prototypes of dedicated solar collector for the storage system for specific climate zones have been designed and developed. An integrated design for the different components and enhance thermo-chemical materials has been tested. Prototypes of the system (for three different climate zones) have been demonstrated and evaluated in a field test. P2ENDURE aims to improve the market up-take through integrated business models, market strategies and other non-technical issues.

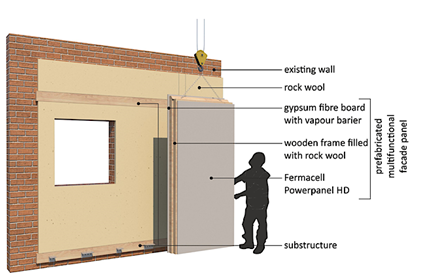

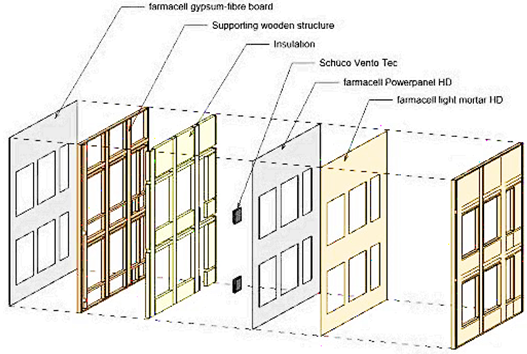

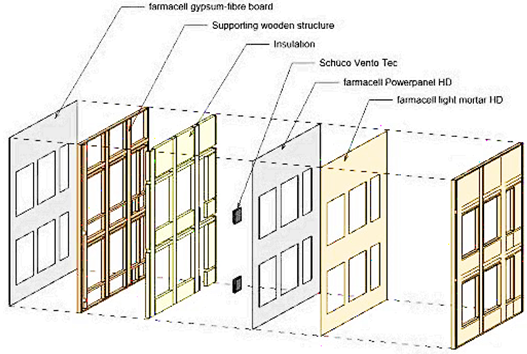

Proposed P2Endure multifunctional Fermacell panel

FC multifunctional panel was designed by consortium partner - Fermacell. Fermacell knowledge and expertise will allow to integrate different installations (like HVAC) within the facade panel and to perform the design in order to fill the durability, thermal and fire resistance requirements.

The solution that will be developed is a versatile prefabricated facade panel composed from a wooden substructure that will allow integrating: water ducts and pipes, air supply or/and even ventilation channels, heating and cooling functions. Fire properties of the materials that can be applied during retrofitting or building construction depend also on the building height. However - if needed - the wooden substructure can be easily changed to a steel substructure.

Gypsum fire boards are produced by Fermacell according to EN 15283-2 + complementary ETA´s and glass fibre reinforced cement boards according to EN 12467 + complementary ETA´s. In order to make the product “board” applicable and easy to use, Fermacell delivers many construction kits for walls, ceilings, floors, roofs and facades. Within the P2Endure project Fermacell will develop a construction kit “versatile Plug&Play facade for renovation” that will be a solution for deep renovation of existing buildings. The construction kit will be mainly a design guideline how to properly design such a Plug&Play facade with the use of wood or steel substructure in combination with gypsum fibre and/or cementitious boards.

Optimisation plan in P2ENDURE: In order to come closer to the goal of Plug&Play and multifunctianal facade the most important issue that need to be developed and analysed are: the horizontal and vertical integration of all kinds of ducts and the integration of Heating, Ventilation and Air Conditioning devices (HVAC).

Check out the Factsheet

Check out the Factsheet

Proposed P2ENDURE RenoZEB Units

A new product has been selected from the European project RenoZEB (GA No. 768718), a sister project of P2Endure, that targets at improving the nZEB building renovation process through innovative components, processes and decision-making methodologies (https://renozeb.eu/). In this context, Focchi S.p.A. developed a PnP prefab solution for renovating building envelopes. Such technology consists of prefabricated units aimed at simplifying the renovation process in terms of performance, time, and costs.

The unit is a prefabricated component composed by a steel frame which contains several types of layers. Eight typologies of units have been developed to fulfill different building requirements. The units are created and installed following a modular approach to improve the production line, the design, and the installation process. The deep know-how and experience in the fields of building facades and aluminum allow the company to manage each step of the design process (design, production, and installation).

The inclusion of the RenoZEB units in the P2Endure project is linked to the P2ENDURE Ancona demo case.

The product modularity simplifies both the design of the whole façade and the installation of the units. In fact, the different types of units can be arranged according to the existing façade layout.

The units have been developed to improve the thermal performance of the building. The analyses of thermal behaviour of the components have been performed using a detailed calculation method. The thermal conductivity (U) of the materials and parts of the units has been studied according to Annex A of BS EN ISO 10077-2 and BS EN ISO 10456. The vision double glazing unit has a thermal transmittance of 1.0 W/m2K. The thermal transmittance of the entire curtain wall has been calculated in accordance with EN 13947. As an example, the U value for the UN-001 is about 0.4 W/m2K.![]()

Check out the Factsheet

Check out the Factsheet

Proposed P2ENDURE BEAM Prefab Facade

With the product Beam the outer layers of the front facade, the rear facade and any side walls of single family homes get replaced. A façade of newbuild quality will be installed instead. All frames will be replaced by frames and glazing of new build quality. The insulating quality of the facades will also structurally be improved and maintenance will be minimized. Accents are applied in the form of window layouts and high-quality finishes. The facade is being smartly and quickly renewed, resulting in improved comfort and a fresh look. The façade can last a long time after the procedure is finished!

.png)

Check out the Factsheet

Check out the Factsheet

Proposed P2ENDURE Cocoonz Prefab Facade

The Cocoonz facade is a minimal weight prefabricated facade component based on techniques used for the back of insulated trucks. Special is the fact that the element is frameless. Using polyester for strength the only other material used for the base of the component is PU insulation. The new façade element is placed in front of an existing dwelling using support pieces placed on the basis of the building.

Check out the Factsheet

Check out the Factsheet

Proposed P2ENDURE Aluminium Facade Component

Aluminium façade, with high-efficiency glass (HR++ ) and sun

protection isolation glass. It recommended for quick renovation

covering the building rapidly to prevent additional water/wind

damage and speeding up renovation process. In Enschede

demonstration site Kawneer RT62 system with HR++ (6-15-4) glazing,

U=1,1 W/m2K, ZTA=27%, with thermal decoupling is applied.

Check out the Factsheet

Check out the Factsheet

Proposed P2ENDURE Prefabricated Bathroom Module

The prefabricated plug & play bathroom is a fully functional and finished

bathroom module. The bearing structure is made of a steel frame and steel

floor with traditional concrete and floor tiles. The insulated metal stud

separations walls with plasterboard are finished with ceramic tiles. The

lowered vinyl ceiling attached to the wooden deck is equipped with

integrated led-lights. Bathroom equipment as toilet, shower, shower screen,

sink and faucets are already preinstalled in the factory.

The unit is placed in the building and it is connected to the building grid

with plug & play connectors.

Check out the Factsheet

Check out the Factsheet