TOOLS

Proposed P2ENDURE IEQ control systems.

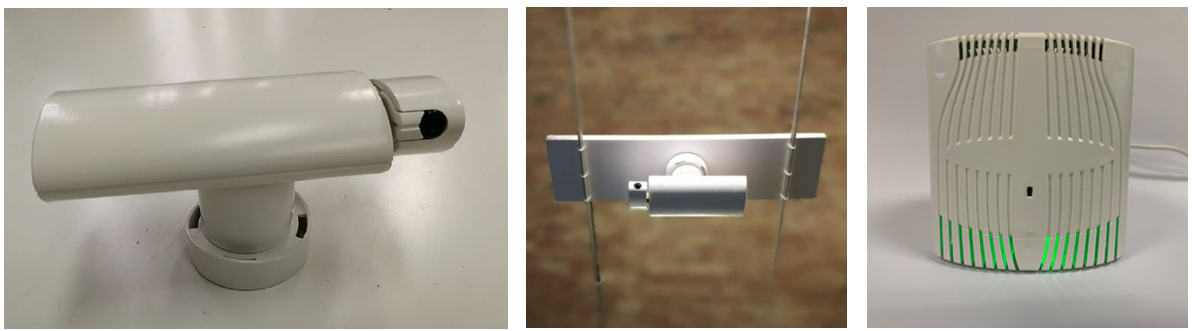

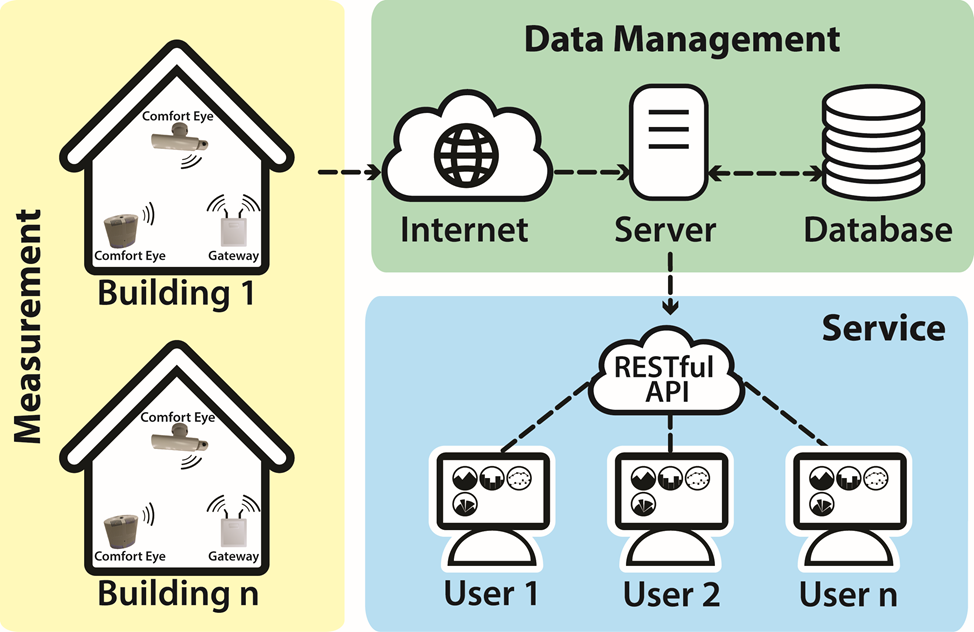

"Comfort Eye" is a low-cost sensing device, which allows real-time monitoring of indoor thermal comfort and indoor air quality. It is composed by two nodes, the ceiling node, and the desk node, with the sensing capability and one gateway for data collection and connection with the remote server.

![]()

The

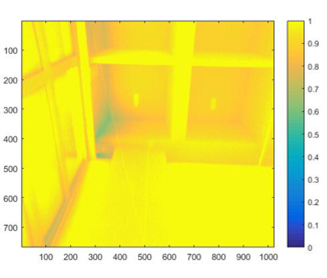

ceiling node is based on a microcontroller and a set of sensors and embedded

algorithms to derive Predicted Mean Vote index (PMV) for multiple subjects in

different positions of the room. The technician installs the scanning system on

the ceiling of the room and connects it to the control unit. The system scans

continuously all the surfaces to measure their average temperatures and sends

the results back to the control unit. Two main advantages are provided by this

solution:

- Multipoint measurements of the mean radiant temperature with only one sensor. Give the geometry of the room, several locations can be chosen to apply the calculation of the mean radiant temperature (e.g. near and far from the window).

- Together with information about comfort, thermal maps of the indoor surfaces are available and that can be used to track the thermal performance of the building envelope (e.g. tracking surface temperature of the external wall, recognizing cool zones etc.).

The desk node is based on a set of sensors to monitor air temperature, relativity humidity, CO2, particulate matter, and illuminance. As for the IR scanner, this node is equipped with a Wi-Fi module for data transmission with the gateway.

The advantages of Comfort Eye are non-invasive multipoint measurement, interoperability and ease of integration and installation. The software developed in the control unit applies all the embedded algorithms and calculations in agreement with ISO standards to derive real-time PMV (and so the thermal sensation) of the user/s within the indoor environment, Key Performance Indicator (KPI) about the indoor air quality and can provide these data as output [to other devices, Building Management System (BMS), etc.]. The system is flexible, from both hardware and software side, so to allow the development of customized solutions for the different applications and scenarios.

The system can perform the measurements and send data to other devices through different communication protocols (e.g. Bluetooth, ZigBee, Wi-Fi, etc.). For example, the user can communicate with the tool through its smartphone and a simple Graphical User Interface (GUI) developed for mobile devices, or through customized dashboards connected with the data stored in a MySQL database.

The device consists of 4 parts:

- The IR (infrared) scanning system, which must be fixed on the ceiling of the room and allows the continuous measurement of surface temperatures.

- The desk node used to acquire environmental quantities used for thermal comfort and indoor air quality assessment.

- The control unit, which manages the data flow between the sensors and from/to the user interface and performs the calculation of thermal comfort for multiple positions.

- Additional Android device or PC (optional), with dedicated GUI, to communicate with the system (input management, data storing, historical data analysis etc.).

For a long-time monitoring and remote-control purposes, an SQL database connection has been developed. It allows the remote monitoring of the room conditions and the interaction with the system. This could allow the application of Comfort Eye in several contexts and scenarios, e.g. for a better microclimate control by means of BMSs (Building Management Systems) and HVAC (Heating, Ventilation and Air Conditioning), without the need of a direct interaction between the systems.

In summary, the embedded algorithms allow the provision of continuous maps or discretised distribution of thermal comfort index, mean radiant temperatures and indoor air quality index. The interaction with the common HVAC system or building management system can be done easily through TCP/IP, RS serial and other home automation protocols. On the other hand, the interaction with the user (the person standing in the room) and the technician can be done through an Android app via a Bluetooth connection.

Proposed P2ENDURE connection to energy grid and RES production.

P2ENDURE targets maximum flexibility in power generation (heat and electricity), distribution and usage. Although power generation devices are becoming more integrated in building components such as facades and roofs, they are still not able to deliver all required energy at the right time. At the district level though, a self-supporting system with different kinds of local generation and storage systems is technically feasible, but the current grid operating systems are not designed to offer the coordination and control for such a network. Therefore, dependency on grids that serve as back-up systems remains crucial.

P2ENDURE will propose innovative solutions for RES (Renewable Energy Sources) and energy grid through the following three-step approach:

- to pursue the best utilization of suitable portions of the building-envelope to lodge the RES production [photovoltaic (PV) and thermal systems], in order to optimize the direct use of the electricity/heat self-produced by these devices;

- to promote the best utilisation of PnP compact energy storage systems at building level, both to consolidate the market penetration of technologies already available on the market (TRL - Technology Readiness Level 8+) and to boost the implementation of systems that are being developed by P2ENDURE consortium partners and stakeholders in other European projects;

- to promote the development and deployment of combined heat and power (CHP) plants, associated to centralized storage systems, within neighbour/district configurations, assisted by control systems (two-way flow of power both for heat and electricity), to enhance their potential of lowering the shift between RES production and end-user demand.

Proposed P2ENDURE thermal and acoustic scanning technologies.

In P2ENDURE, the Quality Controls for prefab panels will be adopted to provide data for the ICT Platform. The main purpose is to eliminate or reduce the quality gap between the design and construction phase through self-inspection and self-instruction techniques connected with an enhanced Augmented Reality (AR) and a detailed Building Information Model (BIM).

The following functionalities using advanced low-cost sensors geo-referencing of the 3D data will be deployed at live demonstration projects in P2ENDURE for:

- Thermal bridges detection: infrared method for a quantitative evaluation of the thermal irregularities (different material, corners, moisture) in building components.

- Thermal transmittance degree: measurement of the thermal transmittance of the building components using thermal camera. The innovative procedure developed in the INSITER project reduces the duration and the uncertainly of the test in respect to the actual standards and techniques used on site.

- Structural integrity diagnosis: non-contact ultrasound probe for the evaluation of panel structural integrity by fast automatic scanning.

- Acoustic leakages detection: evaluation of the acoustic performance of the envelope (transmission loss and acoustic leakages) using a MEMS (Micro-Electro Mechanical Systems) array of microphones.

- 3D geometric scanning and reconstruction: integration of the thermal and acoustic measured data with the points cloud obtained from a 3D laser scanner investigation.

- Continuous update of the Building Information Model can be performed in order to have a complete and detailed time history of the performance evolution of the building and of each building components.

Proposed P2ENDURE 3D scanning (geomatics) – laser and photogrammetry.

Applications of 3D laser scanning technologies range from the building scale to environment assessment, up to infrastructures, for refurbishment/renovation projects, to manage the construction site or to condition assessment. Different devices can be used depending on needs and application (exterior/envelope, interior morphologies, accurate inspection aimed at energy refurbishment, etc.). Laser scanners have increased their efficiency exponentially. More data can be acquired and higher accuracy can be achieved over longer ranges thanks to advancements in sensor technology. Today market offers a lot of different devices for indoor and outdoor innovative applications (mobile mapping, civil infrastructure, airborne scanning, unmanned, hydrographic, bathymetric, mining and terrestrial, etc.). Today several 3D data capturing technologies are available on the market, even in combination with different sensors, providing new methods for condition assessment survey based on predictive analysis (diagnostic) and non-destructive procedures (thermal imaging, level of reflectivity, integrated sensors, spectrophotometry, and sonic surveys). 3D survey technology allows spending more time in the office, and less time in the field. It enables to work faster, make more informed decisions, and reduces the risk of measure/evaluation errors, with a great economic impact. The hardware solutions can create a digital 3D image of anything in reality, from an object to a whole environment. Software solutions can extract many different information (visualize, measure, map, inspect, document). Different parameters such as quality indicators, time-consumption, cost-effectiveness, results accuracy and reliability depend from different available technologies.

Today the market offers a wide range of technologies and devices for 3D capturing, and instruments are more and more accurate and fast. Current gaps are related to the amount of data (time consuming process) and the technological integration between different kinds of devices. While sensor technology develops, the amount of 3D point cloud data acquired increases rapidly, approaching near real time observations. 3D point cloud data is increasingly needed for decision making in smart systems.

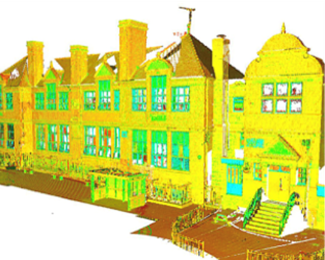

Related with the intended demonstration projects, some practical examples of 3D scanning in combination with prefab panels for deep retrofitting of heritage buildings are as follows:

- Case school building in Tilburg, NL – Project transformation of the school building (cultural heritage from post-war rebuilding period). The building will be fully 3D scanned and refurbished with prefabricated façade panels. The specific details of this functionalistic building are straightforward (industrial detailing). The façade panels will be constructed on the base of steel frame construction. Production of these panels will take place computer-controlled and in-factory.

- Case Lidwina Monastery (reserve project) in Tilburg, NL – Retrofitting including re-insulation of a large-scale historic building. At a design level, the renovation actions for this historic building will be varied. The exterior facades which can be observed from public space with will be renovated. The other exterior facades which can only be seen from inner / private space will possibly be subjected to major change and/or building extension. 3D scanning this building will contribute to an efficient renovation (fast assembly, low material waste, minimal risk errors). The 3D model will be an effective instrument to control computerized production process of the facade panels (in this case steel frame elements or timber frame) and integrated technical modules (technique, sanitary, kitchen).

Proposed P2ENDURE on-site 3D printing and robotics.

P2ENDURE further develops and implements robotic technologies for on-site 3D printing for façade retrofitting. This solution works with various sorts of materials, yet a mix of Thermosilit and limestone is currently preferred to create effective layers of insulation. 3D printing is primarily used to create plastering with special limestone material on concrete walls, ventilation ducts, or water pipes. It gives a 3D design exterior finishing in combination with painting. 3D printing is also used to create a façade layer with any kind of materials suited for the new or retrofitted building structure. In combination with robotic technologies, mounting of windows or other PnP prefab components can also be done very effectively and efficiently on-site. The robots are controlled by an on-site scanning and coordination system. 3D BIM model (currently based on Revit software) is used to pre-programme the robots and on-site processes. By using robots, the number of construction workers on-site can be kept up to 2 or 3 persons. No scaffolding is needed.

The innovative advantages of P2ENDURE on-site 3D printing with robotics are:

- high precision retrofitting process, especially with insulation work ensuring there is no thermal/cold-bridge

- avg. 25% saving of labour effort and respective costs, reduced of workload by craftsman on-site

- large possible variations of insulation thickness around windows

- use of low embodied-energy insulation material (a special sort of limestone): 90% recyclability of Thermosilit material with U-value (in 25cm thermosilit) = 0.21 against 25 times lower embodied energy than the typical rockwool material

- largely stone-based materials without no/limited additional chemicals

- great potential for re-use or re-cycle of components and materials, easy mounting and de-mounting by robots.

The working process of ‘3D printing and milling on-site’ can be summarised as follows:

- 3D laser scan and creation of 3D Revit BIM model using drone or camera, with robot arm assistance on-site if necessary. This state-of-the-art technology already exists.

- Upload of the 3D model to P2ENDURE interface (cloud based) utilising various kinds of post-processors.

- The interface creates accurate on-site work packages for the robot / robot arm. This is done using available postprocessors and the new P2ENDURE interface.

- Robot operated by construction workers performs the plastering, milling / finishing, or painting work on-site.

- The new interface through iPad guides the worker to the right position as he starts to operate the robot that is guided by the 3D model.

3D printing of the first gable of the Korsløkken demonstration case.

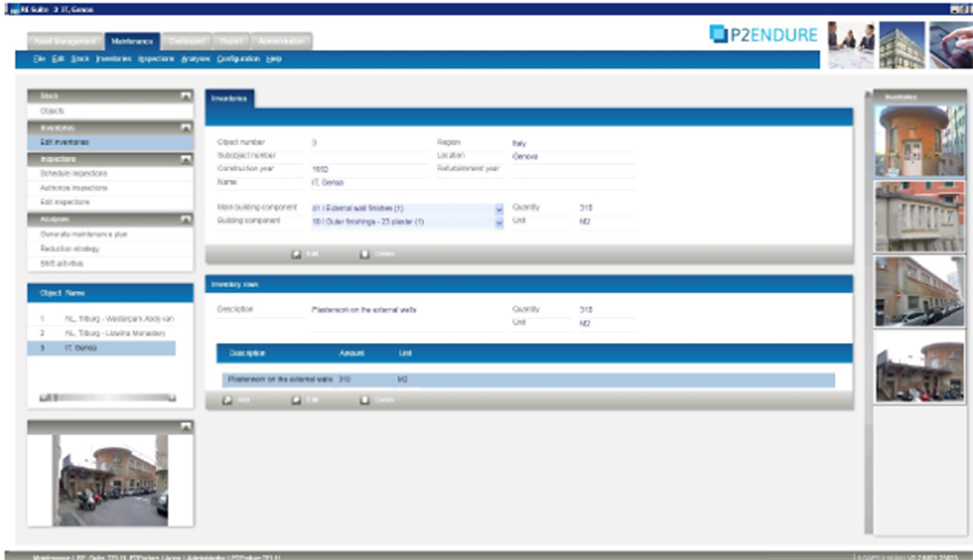

Proposed P2ENDURE ICT tool RE Suite

Software solution that supports collecting, structuring, analysing and disseminating information of buildings and civil infrastructure. Supports the entire life-cycle of real estate and information management. Condition assessment tool for building renovation and for life-cycle cost analysis and asset management.